+91-8828813630

Difference Between Sailma 350, Structural Steel, and Tiscral — When to Use Each

Welcome to This Week’s Deep Dive into the World of Steel Materials

An area that often confuses engineers, builders, and procurement specialists alike. If you’ve found yourself wondering about the distinctions between Sailma 350 plate in India, structural steel plates, and Tiscral, you’re in the right place. Today, we’ll break down what sets these materials apart, when to choose each one, and how international standards like UNS, DIN, EN, and JIS guide their applications. Whether you’re working on a heavy-duty project or simply curious about steel, this post will clarify things with easy language and practical insight.

Understanding Sailma 350 Plate in India: What Makes It Special?

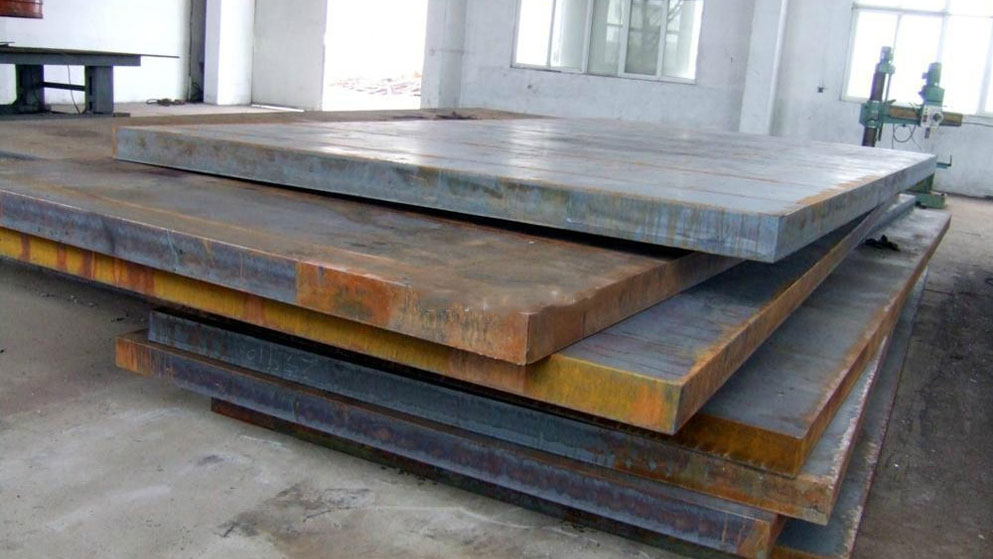

Sailma 350 is a popular grade of wear-resistant steel plate, especially prized in industries like mining, construction, and earthmoving. What sets the Sailma 350 plate apart is its high hardness level—roughly around 350 Brinell hardness—which ensures remarkable resistance to abrasion and impacts. In India, these plates are often sourced following stringent quality checks to meet standards similar to ASTM and EN norms.

But what about standards like UNS or JIS? The UNS system typically catalogues materials in the U.S., while JIS (Japanese Industrial Standards) includes similar grades designed for wear resistance. DIN and EN, European standards, often provide equivalent steel types but with slight chemistry or hardness variations. This means that while Sailma 350 mainly follows local specifications adapted from these international benchmarks, it’s engineered to balance toughness with hardness, a must-have for plates exposed to harsh working conditions.

Structural Steel Plate: The Backbone of Construction and Fabrication

When you hear “structural steel plate”, think versatility and strength. Unlike high-hardness plates like Sailma 350, structural steel plates are designed primarily for load-bearing applications, such as building frameworks, bridges, and heavy machinery. These plates are made to withstand tensile forces and provide the basic skeleton for any major structural project.

Structural steel follows numerous standards globally—EN 10025 is a common European benchmark, ASTM standards dominate in the U.S., DIN norms guide many German productions, and JIS controls the Japanese market. In India, many structural plates comply with IS standards that align closely with these global references to ensure safety and performance. The key variation here is that structural steel is generally more ductile and weldable, which is critical when constructing buildings or infrastructure where flexibility and strength matter more than hardness.

Tiscral: The Niche Player in Corrosion and Wear Resistance

Tiscral, though less commonly known than Sailma or conventional structural steel, finds its niche in environments where corrosion resistance is essential without sacrificing wear capabilities. It is often an alloyed steel with specific chemical properties tailored for applications where both durability and resistance to rust or chemical damage come into play—think chemical plants, marine structures, or specialised industrial equipment.

Many international standards touch on alloys similar to Tiscral. For example, EN and DIN standards categorise various stainless and alloy steels, while JIS covers corrosion-resistant grades catering to Japan’s robust shipbuilding industry. In India, Tiscral-like plates are used in sectors demanding long-term reliability in harsh conditions, thanks to their chemical composition and heat treatment processes.

Choosing the Right Plate: Combining Standards and Application Needs

So, when do you pick Sailma 350, structural steel, or Tiscral? Here’s the short version: If abrasion resistance is your priority, especially in mining or heavy earth-moving, Sailma 350 is likely your best bet. For construction frameworks or industrial support structures, structural steel plates come into play, offering strength, ductility, and ease of fabrication. If your project deals with corrosive environments or requires alloyed steel with both wear and corrosion resistance, Tiscral is the material to consider.

Keep in mind that all these materials must meet relevant standards such as UNS, DIN, EN, or JIS to ensure quality and performance. Knowing how these standards apply can help in selecting the right supplier and guaranteeing consistency—especially important in a diverse market like India’s steel industry, where variations in material quality can impact project longevity.

Final Thoughts: Making Steel Work Smarter for You

Navigating steel grades can feel like decoding a complex puzzle, but understanding the distinct roles of Sailma 350 plate in India, structural steel plate, and Tiscral removes much of the guesswork. Each has its unique strengths shaped by industry standards worldwide and adapted to local needs. Whether you’re managing a construction site, overseeing mining operations, or specifying material for chemical plants, this knowledge ensures you pick the right steel that fits both your technical requirements and budget.

Thanks for reading! Next week, we’ll explore emerging trends in eco-friendly steel production and how these innovations might reshape your projects. Until then, keep forging ahead with confidence and an eye for quality.