+91-8828813630

How Precision Sheet Metal Fabrication Impacts Product Quality

Manufacturing Excellence and the Role of Precision Sheet Metal Fabrication

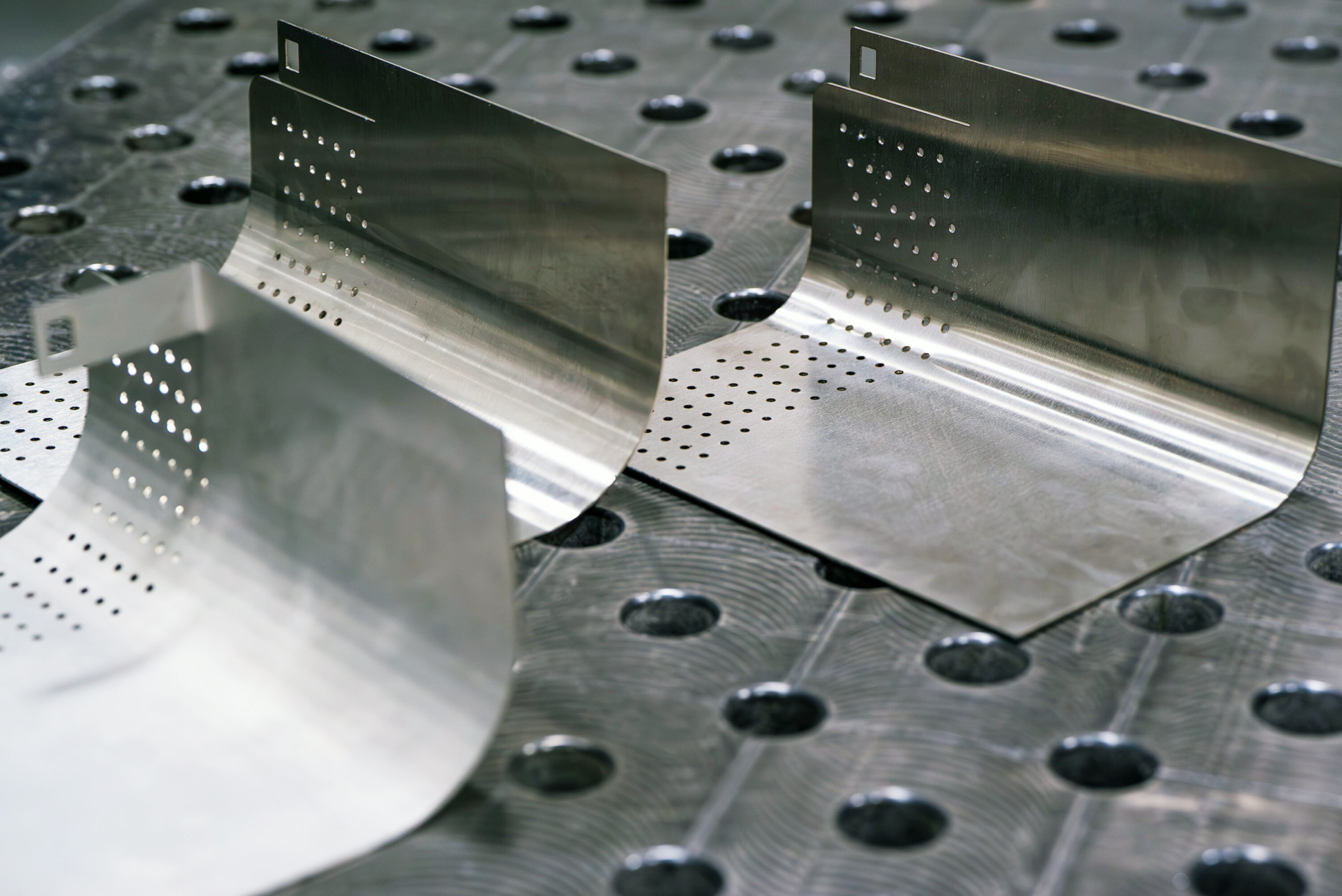

Manufacturing excellence isn't just about producing parts—it's about creating components that perform flawlessly under demanding conditions. Precision sheet metal fabrication stands at the heart of this commitment, transforming raw materials into engineered solutions that power India's automotive, aerospace, construction, and energy sectors. When you're working with specialized materials like Sa 387 Gr 22 Cl.2 Plates or high-strength S690ql Plates, the fabrication process becomes even more critical to ensuring structural integrity and operational reliability.

The relationship between fabrication quality and final product performance can't be overstated. Every cut, bend, and weld directly influences how a component will function in its intended application. Whether you're manufacturing pressure vessels using Sa387 Gr.22 Cl 2 Steel Plates or creating structural frameworks for industrial machinery, the precision achieved during fabrication determines longevity, safety, and cost-effectiveness.

India's manufacturing landscape has witnessed remarkable growth, with companies increasingly adopting advanced fabrication techniques to meet global quality benchmarks. The difference between adequate and exceptional products often lies in understanding how various fabrication parameters—from material selection to finishing processes—work together to create superior outcomes. Modern manufacturers who grasp this connection gain a competitive edge, delivering products that don't just meet specifications but exceed performance expectations in real-world applications.

1. Understanding Precision Sheet Metal Fabrication Techniques

The foundation of exceptional product quality begins with mastering the core fabrication processes that transform raw metal sheets into functional components. Sheet metal cutting techniques form the first critical step, where manufacturers employ various methods to separate material with exacting precision. Traditional mechanical cutting has evolved significantly, giving way to advanced thermal and abrasive processes that deliver cleaner edges and tighter dimensional control.

Core Fabrication Processes

Cutting operations set the stage for everything that follows. Manufacturers in India's thriving industrial hubs utilize multiple approaches—from conventional shearing for straight cuts to plasma cutting for thicker materials. The choice depends on material type, thickness requirements, and desired edge quality. Modern facilities integrate water jet cutting for materials sensitive to heat-affected zones, ensuring the base metal properties remain unchanged.

Bending transforms flat sheets into three-dimensional forms through controlled deformation. Press brakes equipped with precision tooling create accurate angles, while factors like material springback and grain direction influence the final geometry. Skilled operators calculate bend allowances to compensate for material behavior, ensuring parts meet exact specifications.

Welding joins separate components into unified assemblies. TIG welding provides superior control for thin-gauge materials, while MIG welding offers faster production rates for heavier sections. The selection impacts joint strength, appearance, and distortion control—all critical factors in maintaining product integrity.

Advanced Technology Integration

CNC machining revolutionizes how manufacturers achieve repeatable accuracy across production runs. Computer-controlled equipment eliminates human error, executing complex cutting patterns with micron-level precision. These automated systems process design files directly, reducing setup time while maintaining consistent quality from the first piece to the thousandth.

Laser cutting accuracy represents the pinnacle of modern fabrication capabilities. High-powered laser beams vaporize material along programmed paths, creating intricate geometries impossible with conventional methods. The non-contact process eliminates tool wear concerns, while the narrow kerf width minimizes material waste. Indian manufacturers investing in fiber laser technology report significant improvements in edge quality, reduced secondary operations, and faster turnaround times for prototypes and production runs alike.

2. Importance of Design Optimization in Ensuring Product Quality

Design optimization is crucial for achieving top-notch product quality in precision sheet metal fabrication. When engineers apply Design for Manufacturing (DFM) principles right from the start, they effectively connect creative ideas with practical manufacturing constraints. This methodical approach assesses how design decisions impact production workflows, material usage, and assembly processes. By spotting potential manufacturing issues during the design stage, teams can avoid expensive rework, minimize material waste, and significantly reduce defects that could jeopardize product reliability.

The Role of CAD CAM Software

The introduction of CAD CAM software has transformed how design teams collaborate with manufacturing units across India's industrial sector. These advanced tools empower engineers to craft three-dimensional models with exact specifications, replicate real-world performance scenarios, and produce precise toolpaths for CNC machines. Additionally, CAE (Computer-Aided Engineering) applications offer another layer of validation by forecasting how sheet metal parts will respond under pressure, heat conditions, or dynamic forces. This digital workflow guarantees that what's envisioned on screen translates smoothly into tangible components without unforeseen issues.

The Significance of GD&T Tolerance Control

GD&T tolerance control is a vital element of design optimization that directly influences final product quality. Geometric Dimensioning and Tolerancing provides a standardized language for defining acceptable variations in part geometry. When designers specify appropriate tolerances for features like holes, bends, and surface finishes, they're setting clear quality benchmarks for fabricators to achieve. Tighter tolerances might seem ideal, but they often increase production costs and time. Smart design optimization balances functional requirements with manufacturing capabilities, specifying strict tolerances only where they're genuinely necessary for performance.

Fostering Collaboration for Better Outcomes

The collaborative environment created by modern design tools allows real-time feedback between design engineers and fabrication specialists. This continuous dialogue helps identify opportunities for simplification—perhaps combining multiple parts into a single component or adjusting bend radii to match available tooling. Such refinements don't just improve manufacturability; they enhance the structural integrity and longevity of finished products while keeping production costs competitive in India's price-sensitive markets.

3. Material Selection Considerations for High-Quality Fabrication Results

Choosing the right material is crucial for successful precision sheet metal fabrication. The mechanical properties of the materials you choose will directly affect how well the components perform under stress, temperature changes, and environmental conditions. Different industrial applications require specific material characteristics—what works perfectly for automotive body panels may not be suitable for pressure vessel construction or architectural cladding.

Understanding Material Properties and Their Impact

To understand the relationship between material selection and fabrication quality, it's important to know three key properties: hardness, thickness, and ductility.

- Hardness determines a material's resistance to deformation and wear, making it essential for components exposed to friction or impact.

- Thickness affects structural integrity and weight distribution.

- Ductility governs how easily sheet metal can be formed without cracking during bending or stamping operations.

SA 387 Gr 22 Cl.2 plates properties make them particularly valuable for high-temperature applications in pressure vessels and boilers. These chromium-molybdenum alloy steel plates offer excellent creep strength and oxidation resistance, maintaining dimensional stability even under thermal stress. Their composition allows fabricators to achieve precise tolerances while ensuring long-term reliability in demanding environments.

High-Strength Steel Grades for Modern Applications

S690QL steel plates characteristics include exceptional strength-to-weight ratios and superior toughness at low temperatures. This quenched and tempered steel grade has become increasingly popular in construction equipment, crane manufacturing, and structural applications where reducing weight without compromising load-bearing capacity matters. The material's formability allows fabricators to create complex geometries while maintaining tight dimensional accuracy.

Corrosion resistance steel grades play a vital role in extending product lifespan across marine, chemical processing, and outdoor applications. Stainless steel variants containing chromium and nickel provide passive oxide layers that protect against rust and chemical degradation. Selecting appropriate corrosion-resistant materials eliminates the need for extensive protective coatings, reducing production costs while improving aesthetic appeal.

Material specifications following international standards like UNS (Unified Numbering System), DIN (Deutsches Institut für Normung), EN (European Norm), and JIS (Japanese Industrial Standards) ensure consistency in chemical composition and mechanical properties. These standardized designations help manufacturers source materials with predictable behavior during fabrication processes, reducing trial-and-error and minimizing material waste.

4. Importance of Finishing Processes and Quality Control in Achieving Superior Fabrication Results

The journey from raw sheet metal to a finished component doesn't end with cutting and forming. Surface treatment and rigorous quality verification play decisive roles in determining whether a fabricated part meets exacting performance standards. Controlled finishing processes serve dual purposes—they protect the metal substrate from environmental degradation while ensuring the component maintains its precise dimensions throughout its service life.

Surface Treatment Methods That Define Product Longevity

Sanding, grinding, and painting finishes are critical stages where fabricators transform rough-cut edges and surfaces into smooth, professional-grade components. Sanding operations remove burrs and sharp edges that could compromise assembly or pose safety risks. Grinding techniques create uniform surface textures that enhance paint adhesion and aesthetic appeal. The application of protective coatings—whether powder coating, electroplating, or liquid paint systems—provides essential barriers against corrosion, particularly vital for components exposed to India's diverse climatic conditions ranging from coastal humidity to industrial pollution.

Each finishing step must be executed with precision to avoid introducing dimensional variations. Excessive material removal during grinding can push tolerances out of specification, while uneven coating application creates thickness inconsistencies that affect fit and function. Temperature control during curing processes prevents warping, especially in thinner gauge materials commonly used in electronics enclosures and automotive panels.

Advanced Inspection Technologies Ensuring Conformance

Coordinate measuring machines (CMM) have revolutionized quality verification in sheet metal fabrication facilities across Indian manufacturing hubs. These sophisticated instruments probe multiple points on a fabricated component, comparing actual dimensions against CAD specifications with micron-level accuracy. CMM inspection catches deviations that human inspectors might miss, from subtle warping to angular misalignments in bent flanges.

Statistical process control in fabrication takes quality assurance beyond individual part inspection. By continuously monitoring process parameters—cutting speeds, bend angles, weld penetration depths—manufacturers identify trends before they result in defective parts. Control charts reveal when machines drift from optimal settings, enabling preventive adjustments that maintain consistent output quality. This data-driven approach reduces scrap rates while building confidence in product reliability, particularly important for high-volume production runs serving automotive and construction sectors.

5. Global Standards Governing Sheet Metal Fabrication Quality: A Comprehensive Guide for Manufacturers Worldwide

When manufacturers want to compete in global markets, it's important to understand the international quality standards for fabrication. These standards set consistent quality guidelines that go beyond borders, making it easier for suppliers and clients from different countries to work together.

Understanding Material Grade Identification Through UNS Standards

The Unified Numbering System (UNS) is a universal system used to identify metal alloys and their compositions. UNS standards for steels provide a systematic way to categorize materials based on their chemical composition and mechanical properties. This standardization ensures that manufacturers in Mumbai, Delhi, or Pune can communicate specifications clearly with their counterparts in Germany or Japan when dealing with stainless steel grades like UNS S30400 (commonly known as 304 stainless steel) or carbon steel variants. The UNS designation removes any confusion in choosing materials, which directly affects the strength and performance qualities of fabricated parts.

Harmonizing Manufacturing Requirements with DIN, EN, and JIS Certifications

European standards (DIN and EN) and Japanese Industrial Standards (JIS) create comprehensive guidelines covering everything from material specifications to fabrication tolerances. DIN EN JIS certifications address critical aspects including dimensional accuracy, surface finish requirements, and testing methodologies. Indian manufacturers serving automotive and aerospace sectors particularly benefit from adhering to these standards, as they're often mandatory for components destined for export markets or critical applications.

DIN standards, originating from Germany, provide detailed specifications for sheet metal thickness tolerances, bend radii, and welding procedures. EN standards, adopted across European Union member states, ensure consistency in material properties and testing methods. JIS standards bring precision-oriented approaches developed through Japan's manufacturing excellence, particularly valuable for high-tolerance applications.

Industry-Specific Compliance Requirements

Aerospace manufacturers can't compromise on quality—international fabrication quality benchmarks like AS9100 build upon ISO 9001 foundations while adding stringent requirements specific to aviation components. Automotive suppliers similarly adhere to IATF 16949 standards, which integrate quality management systems with production-specific requirements. These frameworks don't just set minimum acceptable standards; they create a culture of continuous improvement where traceability, documentation, and process control become ingrained in manufacturing operations. You'll find that compliance with these standards opens doors to partnerships with global OEMs and tier-1 suppliers who demand verifiable quality credentials.

Conclusion

India's manufacturing industry is constantly changing and improving, with precision sheet metal fabrication becoming an essential technology in various industries. The automotive sector heavily relies on these advanced fabrication methods to create lightweight yet strong parts that meet strict safety regulations. Construction projects require precisely made structural elements that can endure environmental pressures while preserving the integrity of the design. The advantages of precision sheet metal fabrication for these industries are significant, including improved accuracy in measurements and consistent quality from one batch to another, which minimizes difficulties during assembly.

The steel industry in India is at an exciting point where traditional craftsmanship combines with modern automation. Manufacturers who have adopted CNC machining, laser cutting systems, and automated quality inspection processes are experiencing significant increases in production speed without compromising precision. This technological advancement directly leads to greater dependability of products in the Indian steel industry, giving participants a competitive edge in both local and international markets.

Looking ahead, the integration of Industry 4.0 technologies holds the promise of even greater efficiency improvements. Innovations such as smart sensors that monitor fabrication processes in real-time, AI-driven predictive maintenance that reduces downtime, and cloud-based quality management systems enabling seamless collaboration between design and production teams are reshaping how manufacturers approach the impact of precision sheet metal fabrication on product quality. The future belongs to fabricators who can strike a balance between cost-effectiveness and uncompromising quality standards, delivering products that exceed customer expectations while maintaining sustainable production practices.

FAQs (Frequently Asked Questions)

What is precision sheet metal fabrication and why is it important for product quality?

Precision sheet metal fabrication involves advanced cutting, bending, welding, and finishing techniques to create metal components with tight tolerances. Its importance lies in significantly influencing the final product's performance, reliability, and durability across various industries by ensuring high-quality manufacturing standards.

Which fabrication techniques are commonly used to achieve high accuracy in sheet metal products?

Key fabrication techniques include CNC machining and laser cutting, which provide exceptional accuracy and repeatability. These advanced technologies enable manufacturers to meet tight tolerances and improve overall product quality by minimizing defects during cutting, bending, and welding processes.

How does design optimization contribute to enhancing product quality in sheet metal fabrication?

Design optimization through Design for Manufacturing (DFM) principles aligns product designs with fabrication capabilities, reducing defects and improving reliability. Utilizing CAD/CAM/CAE software allows precise modeling, simulation, and effective communication between design and manufacturing teams, ensuring tolerance control via GD&T standards.

What materials are commonly selected for precision sheet metal fabrication to ensure superior product performance?

Materials such as SA 387 Gr 22 Cl.2 plates and S690QL steel plates are frequently used due to their mechanical properties including corrosion resistance, hardness, thickness, and ductility. Proper material selection directly impacts formability and the overall performance of fabricated products in demanding applications.

How do finishing processes and quality control measures impact the final outcome of sheet metal fabrication?

Controlled finishing processes like sanding, grinding, and painting enhance both aesthetics and corrosion protection while maintaining dimensional accuracy. Quality control tools such as coordinate measuring machines (CMM) and statistical process control ensure conformity to design specifications, resulting in reliable and high-quality end products.

What global standards govern sheet metal fabrication quality and why are they crucial for manufacturers?

International standards including UNS steel grade identifications along with DIN, EN, and JIS certifications establish benchmarks for material properties and manufacturing requirements. Adherence to these standards harmonizes quality expectations worldwide, which is vital for industries like aerospace and automotive that demand consistent precision.